Current Projects

Custom Project

Timing Belt Cover

Here is rendered version of the custom timing belt cover for Hemi 1000hp Hellephant crate engine with integrated dual alternators, electric water pump and full DrySump setup. Can’t wait to start machining this beauty!

Race Car, Subaru Impreza

2007 STI Wide-Body

Completed Work

- Phase 1

Disassembly and cleaning of the vehicule. - Phase 2

Frame welding, Fabrication and installation of the roll cage. Wide-Body kit and fuel tank installation.

Currently Working On

- Phase 3

Front v-mount intercooler and radiator. Quick removal front end.

Front suspension and upright (for wide-body.) Engine placement lowered, fabrication of exhaust and intercooler piping.

Next Steps

- Phase 4

Wiring harness and engine hook up. Hydraulic lines and oil coolers. Transmission and rear differential placement. Dash and center console fabrication and placement. - Phase 5

Strip down and paint. Final assembly begins. Road testing.

For Sale

It is in partnership with the buyer that the final parts list is determined and

confirmation of the build for its intended series homologation is validated. The

recommended use for this racing car is: Time-Attack, Circuit.

Motorcycle 1981 Honda CB900c

Cafe Racer

Completed Work

- Phase 1

Disassembly and cleaning of the motorcycle. Conception of the whole project. Construction and welding of the rear triangle, the fenders and the gaz tank. - Phase 2

CNC custom part for the cockpit, electrostatic black matte powdercoating paint. Engine and transmission reconditionning. - Phase 3

Electrical system completely redone with integrated circuit (PDM – no relay or mechanical fuse.)

Next Steps

Fabrication of the brake calipers, complete hydraulic system.

For Sale

It is possible to reserve the motorcycle before the work is completed. This

motorcycle is aimed at experienced customers. This MooreSport Cafe Racer will

be light, efficient, fast and responsive while driving.

Custom Racing Car Parts for Dan Kroll

Front Uprights

Completed Work

- Phase 1

Consultation. Applied proven concept to new application specific 3D model. All technical and production drawings made and validated. 3D prototype confirmer. - Phase 2

Initial machining of 1st side - Phase 3

Fixture for holding part for 2nd side machining. quality control, and ancillary components (brackets, spacers, lower ball joint, etc)

Next Steps

- Phase 4

Road and racing situations testing.

Availability

Once tested, those parts will be available for every customers.

Research and Development

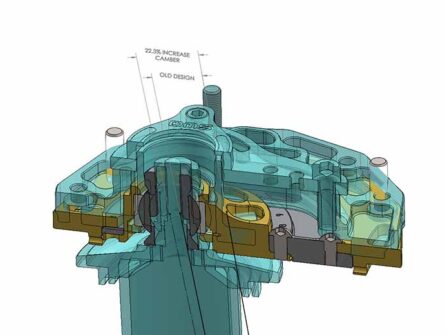

Adjustable Top Mounts

Current Work

Initial brainstorming and concept, sketches, and raw 3d model.

Research & Development. Images shown DOES NOT represent a final version.

Next Steps

Validation of initial concept, fine tuning model, FEA simulation, weight reduction

and validation of the machining process. Prototyping and testing before going into

production.

Availability

Pre-order will be available when production starts.

Motorsport grade quality parts, 100% customized to your needs.

Start Your Own Project

Personnalized Offer

From project assessment to final assembly, the team at MooreSport works with

you to deliver quality components that meets the highest standards within the

motorsport industry.

Specialization & Possibilities

We are specialized in customized projects of chassis and suspension for race

cars, but can also work with engine, drivetrain, many kinds of mounts and

fabrication of small parts.

Our team of experts specializes in optimizing cars and performance parts for all

makes and models: Subaru STI, Dodge Viper, Mitsubishi EVO, Nissan, BMW,

Porsche and much more.

Consultation Services

Benefit from additional expertise for the development of MooreSport machined

systems. Optimize common configurations of a part or an assembly. Ensure

optimal performance of adjustments.